How to Choose a Cost-Effective Safety Light Curtain: A Comparison Guide on 5 Key Parameters

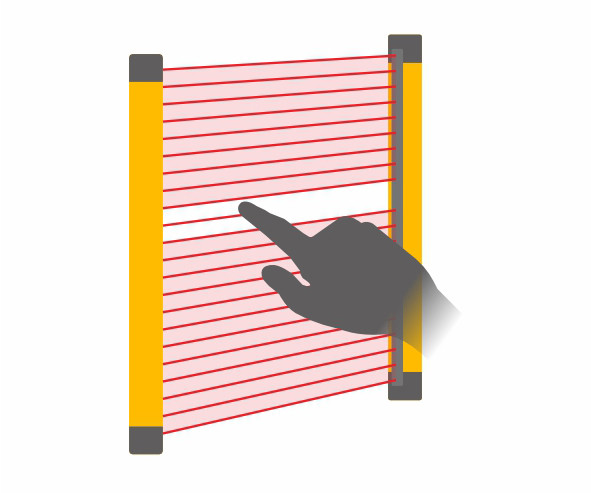

Light Beam Spacing (Resolution): Determines Protection Accuracy

• Core Function: A smaller beam spacing enhances protection accuracy, making it ideal for safeguarding more sensitive body parts.

• Guidelines:

10/14/20mm Spacing

Ideal for finger protection (e.g., paper cutters, precision stamping machines).

20/30/40mm Spacing

Suitable for palm protection (e.g., assembly lines, automated welding equipment).

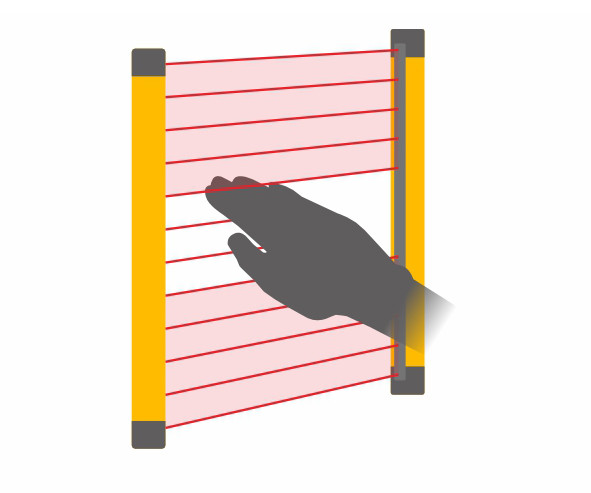

40/80/200mm Spacing

Appropriate for arm or full-body protection (e.g., large punching machines, palletizing systems).

• Cost-Effectiveness Strategy: Choose the minimum required spacing based on your needs to avoid unnecessary costs. For example, selecting 20mm spacing instead of 10mm for palm protection can reduce expenses by approximately 30%.

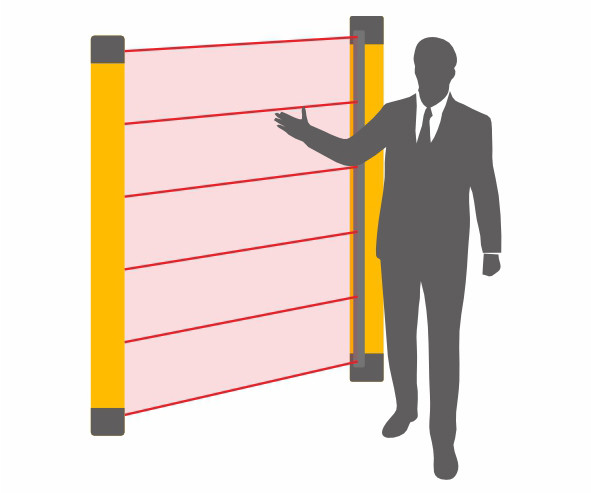

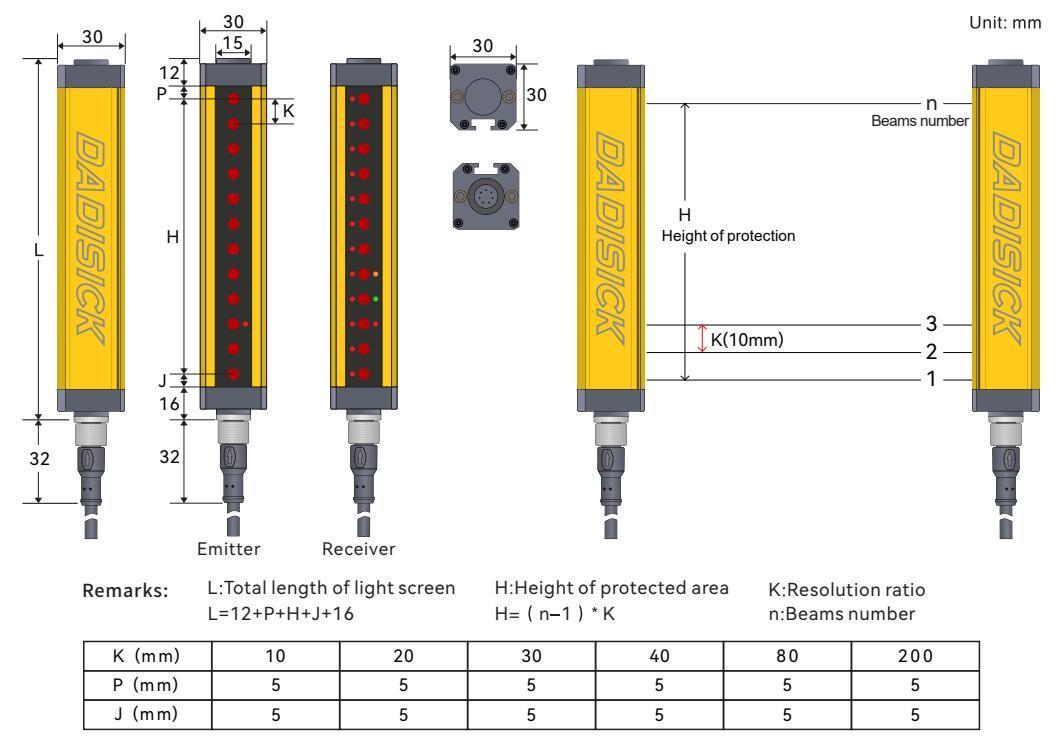

Protection Height: Aligning with Equipment Safety Zones

• Calculation Method

Effective Protection Height = Beam Spacing × (Total Number of Beams - 1).• Customization Needs

Configure the light curtain to cover the actual hazardous area—such as the entire mold opening for a punching machine.• Selection Tips

Distinguish between “Total Light Curtain Height” and “Effective Protection Height.”

DADISICK’s technical documentation for each series clearly specifies these parameters.

For non-standard safety light curtain applications, we offer customization services. The DADISICK QCE series of general-purpose safety light curtains supports up to 200 beams, covering most application scenarios.

Operating Distance: Adapting to Equipment Layout

• Selection Criteria

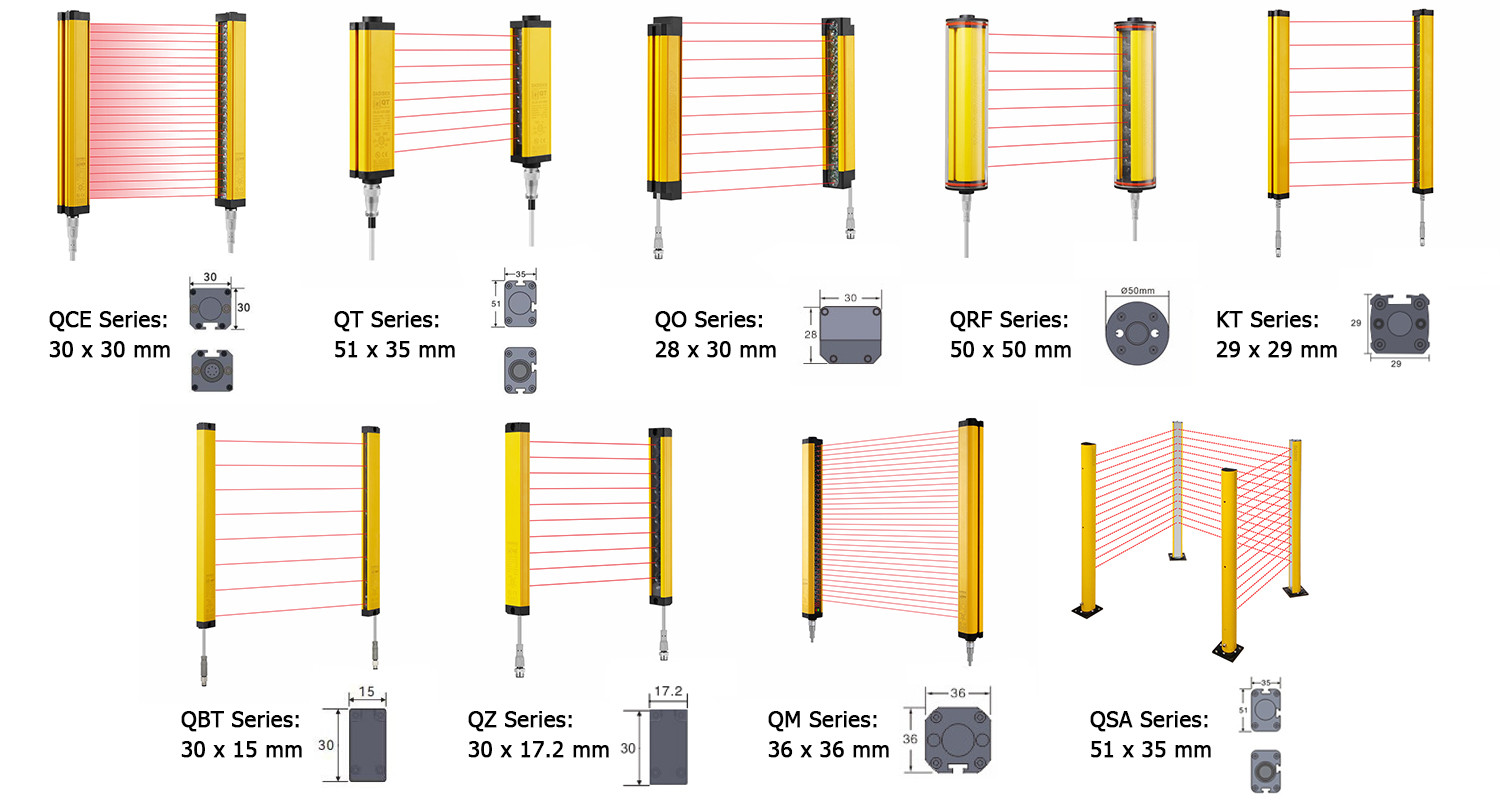

Short Distance (0–6 meters): Ideal for compact equipment (e.g., small machining centers). Ensure the light curtain’s cross-sectional dimensions match the available installation space.

Long Distance (6–45 meters): Suitable for large assembly lines or warehousing equipment. In such cases, select models with strong anti-interference capabilities (e.g., those rated IP65).

• Cost Optimization

For extended distance applications, consider using relay amplifiers in place of high-power models to save over 20% in costs.

Output Signal Type: Ensuring System Compatibility

• 2 OSSD (Output Signal Switching Device): NPN NC, PNP NC, NPN NO, PNP NO

• Key Verification: We provide signal compatibility comparison data for safety light curtains from different brands to help customers avoid retrofit costs.

Brand | From network | DADISICK |

|

|

Models

|

GL-R72HG | QMT72-20-1420-2BD |

|

GL-R80HG |

QMT80-20-1580-2BD | ||

GL-R88HG | QMT88-20-1740-2BD |

||

GL-R96HG | QMT96-20-1900-2BD | ||

Beam spacing | 25 mm | 20 mm | |

Protected altitude | 1465mm, 1625mm, 1785mm, 1945mm | 1420 mm, 1580 mm, 1740 mm, 1900 mm | |

Scanning range | 0.2 m - 15 m | 0.3 m - 15 m | |

Response time | 12.2 ms - 14.8 ms | ≤15 ms | |

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 / IP67 | IP65 | |

Connector | M12 | M16 | |

Housing cross-section | 28 mm × 30 mm | 35 mm × 51 mm | |

Safety Certificate | CE, UL | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Safety Certifications and Service Systems: Controlling Hidden Costs

Certification Requirements:

Mandatory Certifications: CE (EN/IEC 61496) and ISO 13849 (safety level must reach PL d or above).

Bonus Certifications: TÜV and UL, which are especially valuable in European and American markets.

Service Cost Comparison:

| Service Type | Risks with Low-Cost Options | Recommended High-Value Solution |

| Warranty Period | ≤1 year; may lead to high hidden repair costs | Opt for brands offering a warranty of ≥3 years |

| Technical Support | Limited to documentation with slow response | Prefer local service teams that provide 48-hour support |

| Spare Parts Supply | Delivery times exceeding 2 weeks | Ensure factory stock availability with delivery within 7 working days |

By thoroughly assessing these parameters and selection guidelines, customers can find a cost-effective safety light curtain that aligns with their application requirements and safety standards. Backed by professional technical support and a comprehensive service system, DADISICK provides reliable products and services for industrial automation safety solutions.

Safety Light Curtain Replacement Solutions

View Catalog

Choosing Your Safety Solutions

You May Also Be Interested In

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety light curtains are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.