How to Choose the Right Safety Light Curtain Manufacturer?

Compare Leading International Brands and Discover High-Performance Alternatives That Cut Costs by 30%!

In industrial automation, safety light curtains are essential devices for protecting both personnel and machinery. Whether used with robotic arms, stamping machines, or automated production lines, their reliability and compatibility directly affect operational safety and efficiency. However, with so many international brands on the market—such as SICK, KEYENCE, and OMRON—choosing a manufacturer that meets technical standards while offering high cost-effectiveness has become a major challenge for many companies. This article will explore industry demands, key selection criteria, brand comparisons, and practical solutions to help you choose the right safety light curtain manufacturer. We will also introduce DADISICK and its unique advantages as a professional alternative solution provider.

Core Customer Needs and Pain Points

Do Safety Light Curtains Meet Core Requirements?

Safety: Safety light curtains must comply with international safety standards (e.g., IEC 61496) to ensure high detection sensitivity and fast response times in hazardous zones.

Compatibility: Seamless integration with existing equipment is essential, including support for mainstream communication protocols such as PLCs and relays.

Stability: Devices must operate reliably over long periods, even in harsh industrial environments with EMI, dust, or high temperatures.

Cost Control: A balance between purchase and maintenance costs is crucial, avoiding unnecessary expenses from brand premiums or extended repair cycles.

The Pain Points and Challenges of Selecting Safety Light Curtains

Brand Dependence: International brands like SICK and KEYENCE are technologically advanced but often expensive and slow to service—posing a challenge for small and medium-sized enterprises.

Technical Barriers: Customers often lack the expertise to fully understand technical parameters (e.g., resolution, detection range, interference resistance) and need professional guidance.

Urgent Replacement Needs: Many companies face discontinued models or part shortages and urgently seek reliable replacement solutions.

How to Choose a Safety Light Curtain Manufacturer: Key Selection Criteria

1. Technical Specifications and Certifications

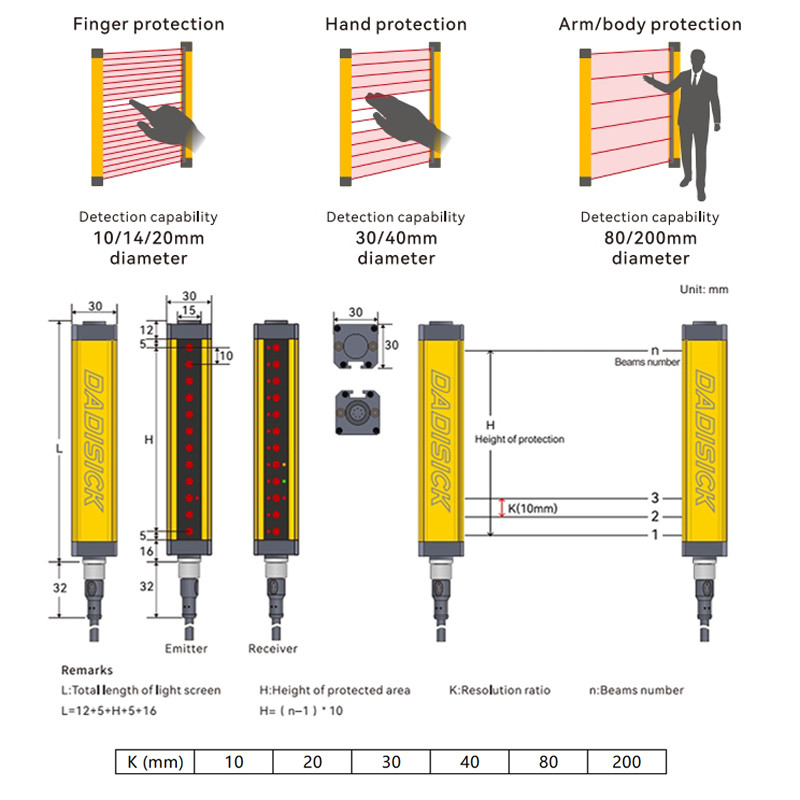

Detection Accuracy and Range: Choose the appropriate resolution based on your application (e.g., ≤20 mm beam pitch for finger protection).

Interference Resistance: Devices should offer EMC resistance and strong light suppression (e.g., sunlight immunity).

Safety Standards: Compliance with SIL3/PL e ratings is essential, ensuring emergency stop response times within ≤100ms.

Compatibility: Support for cascading, blanking functions, and multiple protocol interfaces (e.g., Modbus, Profibus) is recommended.

2. Brand and Service Assurance

Quality Certification: Look for manufacturers certified under ISO 9001, CE, and FCC.

After-Sales Support: A responsive, localized service team ensures fast diagnostics and spare parts supply.

Proven Case Studies: Prioritize manufacturers with successful implementations in high-risk industries such as automotive, chemicals, and logistics.

3. Cost and Long-Term Value

Total Lifecycle Cost: Evaluate not just the purchase price but also maintenance and upgrade expenses—avoiding inflated costs from monopolized brands.

Flexibility: Support for customization (e.g., non-standard sizes or extreme environmental adaptations) adds long-term value.

Comparison of Leading International Brands and Selection Suggestions

| Brand | Advantages | Limitations | Ideal Applications | |||

SICK (Germany) | Industry-leading technology, excellent interference resistance | High cost, slow after-sales response | High-precision detection (e.g., semiconductors, medical) | |||

| KEYENCE (Japan) | Smart configuration, easy setup | Limited customization support | Standardized production lines (e.g., automotive assembly) | |||

| BANNER (USA) | High cost-performance ratio, strong compatibility | Slightly lower safety level (some models) | SMBs and warehouses/logistics | |||

| PILZ (Germany) | Comprehensive safety certification, reliable | Long delivery lead time | High-risk industries (e.g., metallurgy, chemical) | |||

Selection Recommendations:

Limited Budget, High Reliability Needed: Consider cost-effective brands like BANNER or Autonics.

Strict Environments or High Safety Levels: Opt for German brands like SICK or PILZ.

Fast Response and Flexible Service: DADISICK offers international brand-compatible solutions that balance performance and cost.

DADISICK: A Reliable Alternative to International Brands

As a professional manufacturer focused on safety sensor replacements, DADISICK addresses common customer pain points with tailored solutions:

1. Core Advantages

• 1:1 Brand Compatibility: Supports direct replacement for major brands like SICK, KEYENCE, and OMRON—no system redesign needed.

• Cost-Effective: Delivers equivalent performance at just 50%-70% of OEM prices, significantly reducing procurement and maintenance costs.

• Rapid Response: Global inventory coverage enables shipment within 48 hours, with expedited service for urgent orders.

• Localized Support: A Chinese technical team provides full-process support from selection to installation and commissioning.

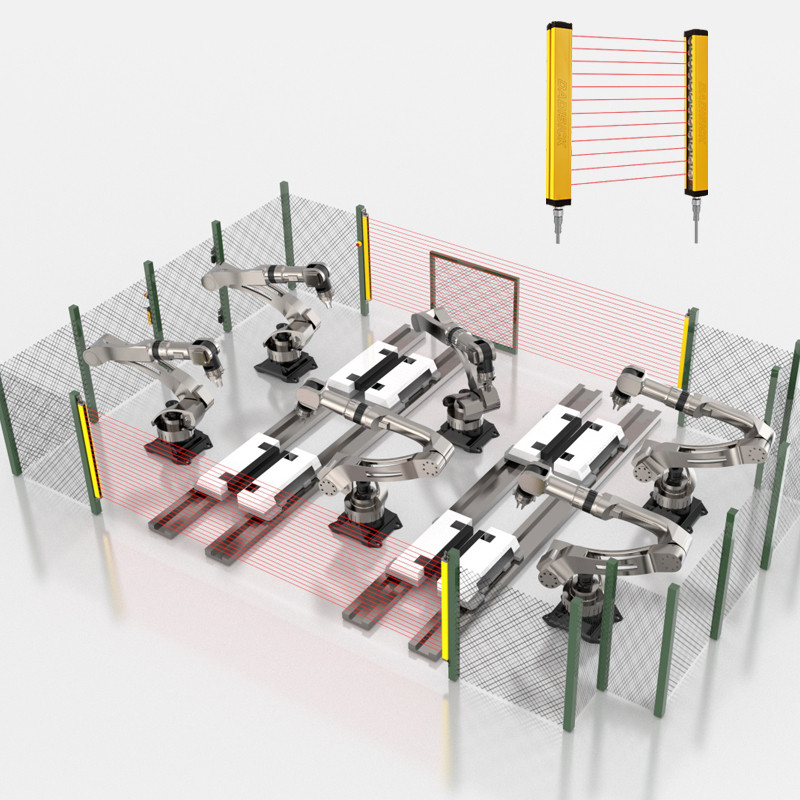

Safety light curtain application in the Automotive Manufacturing

A major carmaker replaced discontinued OMRON light curtains with DADISICK alternatives—installation completed in 3 days with a 60% cost reduction.

Solution: Universal Safety Light Curtain QCE Series

Solution: Universal Safety Light Curtain QCE Series

1. Key Features:

• Strong resistance to electromagnetic and optical interference ensures stable performance in complex electromagnetic environments.

• With a cross-sectional size of only 30×30 mm, the QCE series fits easily into most automation equipment.

• Equipped with an M12 7-pin aviation connector, offering stable connections and excellent compatibility. No rewiring or interface changes are needed during replacement or integration.

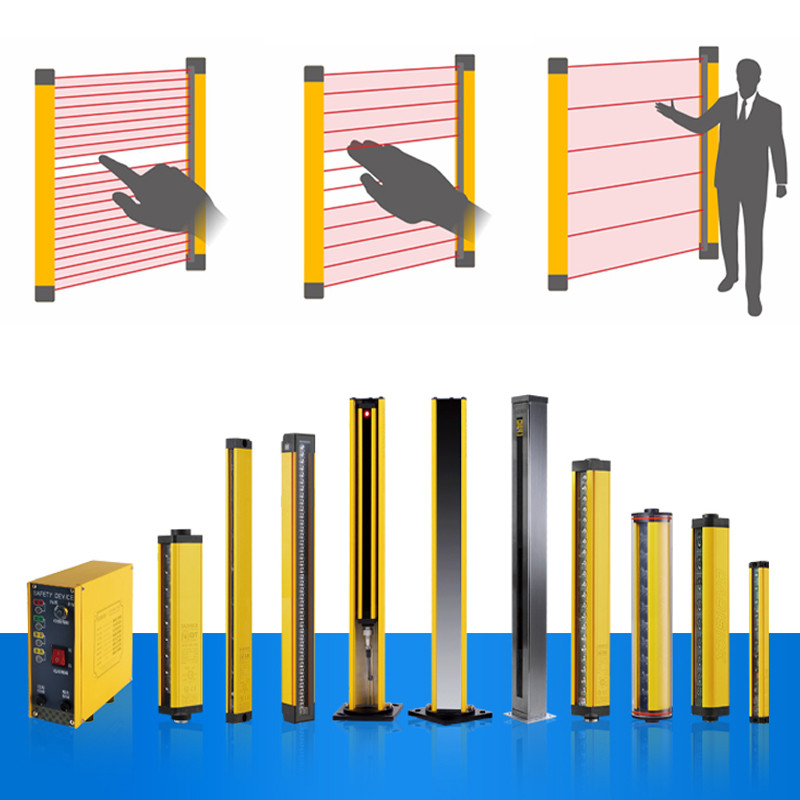

• Available detection ranges include 0.3–3 m and 0.3–6 m. Optical beam spacing options of 10/20/30/40/80/200 mm support various protection levels from finger to full body.

2. Recommended Applications:

Ideal for high-precision hand or body detection in automated machinery such as robotic arms, welding cells, and assembly lines.

Safety light curtain application in the chemical industry

In a long-running chemical production facility, the safety light curtains previously in use—supplied by the well-known brand BANNER—had been in service for many years. As equipment aged and production demands evolved, the plant began exploring alternative solutions to enhance reliability and reduce maintenance frequency. After a careful evaluation, the facility chose DADISICK’s QT Series Long-Range Safety Light Curtains, which successfully passed corrosion resistance tests and have been operating stably for over two years.

Solution: Long-Range Safety Light Curtain QT Series

Solution: Long-Range Safety Light Curtain QT Series

1. Key Features:

• Outstanding vibration resistance and strong anti-interference performance make this model suitable for harsh environments, including those with corrosion, dust, or high temperatures.

• The 51×35 mm cross-section ensures a rugged build, ideal for mounting on machine enclosures or protective doors.

• Standard detection ranges are 0.3–3 m and 0.3–6 m, with a maximum range of up to 45 m — perfect for large-area safety protection.

• M16 7-pin aviation connector allows for fast, reliable setup and easy maintenance.

• Versatile Beam Spacing Options: Supports 10/20/30/40/80/200 mm spacing to accommodate different protection requirements, from fingers to full-body safety.

2. Recommended Applications:

Well-suited for production lines in chemical plants, hazardous area access points, and safety fencing systems requiring mid-to-long range protection.

Safety Light Curtain Replacement Solutions

View Catalog

Choosing Your Safety Solutions

You May Also Be Interested In

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety light curtains are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.