Free Palletizing Robot Workstation Safety Guide: Boost Your Production Efficiency

Robot Palletizing Workstation Safety Requirements

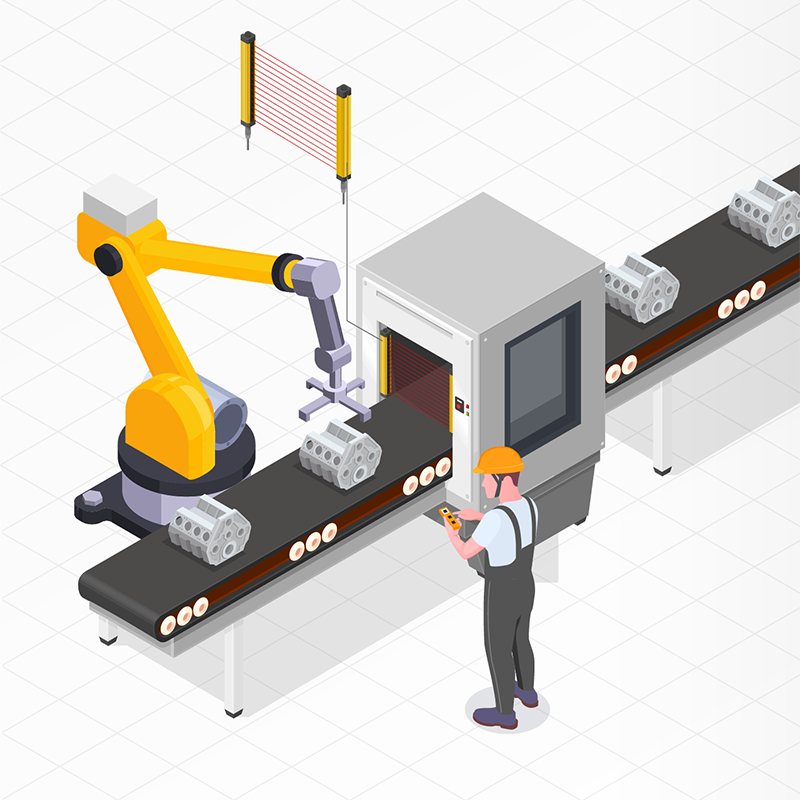

Robot palletizing systems often operate in high-speed environments with frequent material movement and human-robot interactions. Typical risks include:

● Unintended human entry into hazardous zones

● Collision risks between humans and robotic arms

● Emergency stop needs due to equipment failure or object misalignment

Key Safety Devices and Their Functions

● Safety Laser Scanners (e.g., SICK microScan3, Omron OS32C, Pilz PSENscan)

Installation Location: Floor-level at the corners or perimeter of the robot workstation

Function: Create configurable protective and warning zones. When an object or person enters the protected area, the system automatically slows or halts the robot.

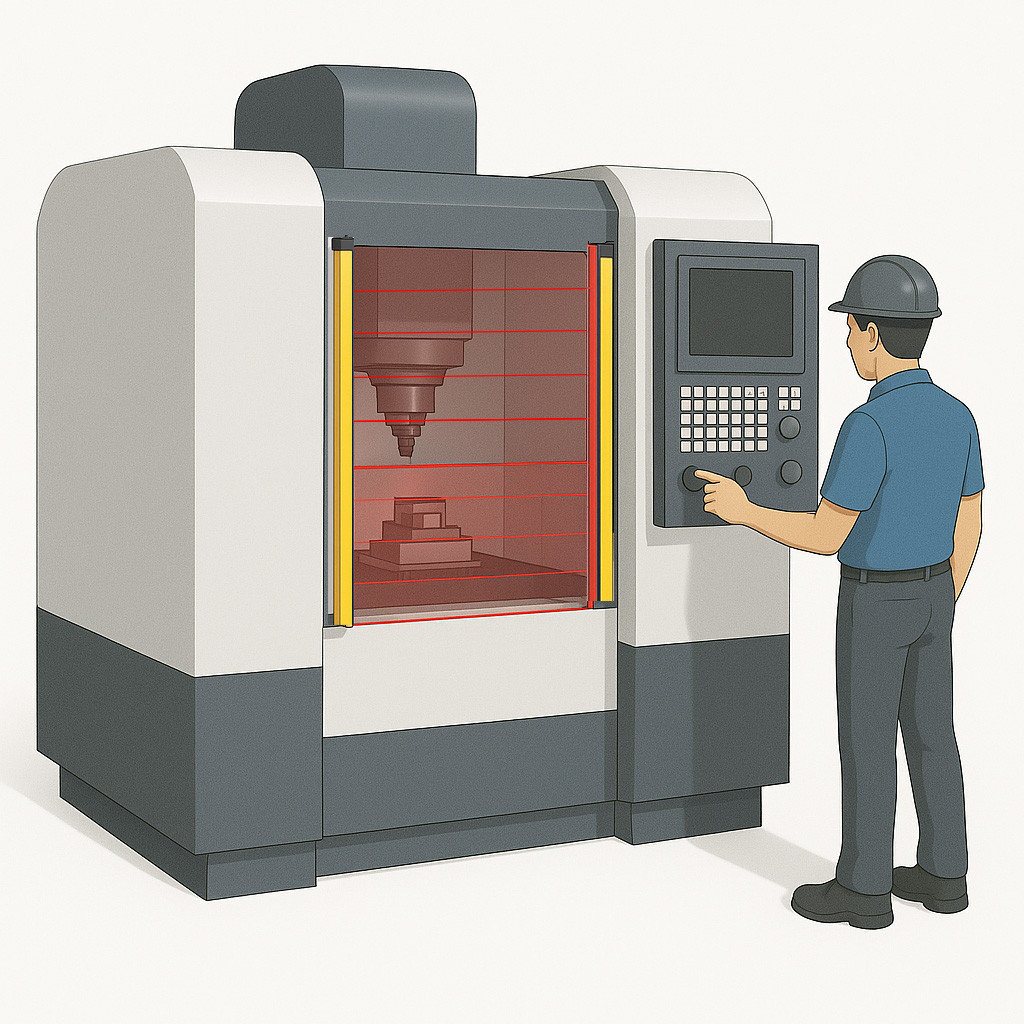

● Safety Light Curtains (e.g., Schneider XUSL, SICK deTec, Banner EZ-SCREEN)

Installation Location: At open access points (e.g., entrances of conveyor lines, pallet exits)

Function: Detect human presence or limbs entering hazardous zones. A signal interruption causes the robot to stop.

● Safety Interlock Switches (e.g., ABB Eden, Omron D4NS, Pilz PSENmech)

Installation Location: On protective doors, gates, or fencing panels

Function: Ensure the robot stops or cannot restart when access doors are opened.

● Emergency Stop Buttons

Installation Location: Readily accessible locations around the workstation (panels, fences, walls)

Function: Immediate manual shutdown of the system in case of emergencies

● Safety Relays / Controllers (e.g., Pilz PNOZmulti, Schneider Preventa, Omron G9SA)

Installation Location: Control cabinet

Function: Evaluate and process input signals from all safety devices and manage logic control of actuators.

● Safety Mats (Pressure-sensitive)

Installation Location: Floor area near manual loading/unloading zones

Function: Detect operator standing or stepping into dangerous areas, stopping robot motion accordingly.

Leading Manufacturer Practices in Robot Workstation Safety

🔹 SICK

• Offers integrated 2D LiDAR solutions like microScan3 for flexible zone setting

• Combines deTec4 light curtains for finger/hand detection

• Strong diagnostics via Safety Designer software

• Modular Preventa range connects XUSL light curtains and safety switches

• Emphasizes plug-and-play diagnostics with Smart Safety Architectures

🔹 Omron

• Compact OS32C laser scanners with 270° scanning angles

• Smart safety relays (G9SP) suitable for mid-sized robotic stations

• Seamless integration with Sysmac automation platforms

🔹 Pilz

• Full-solution provider with PSENscan, PSENmech, and modular PNOZmulti 2 controllers

• Focuses on TÜV-certified safe motion and customizable logic blocks

🔹 ABB

• Offers safety-rated robot controllers with SafeMove functionality

• Recommends use of Eden interlocks for fence doors

• Integration with safety PLCs and fieldbus communication

• Known for compact and rugged EZ-SCREEN light curtains

• Also offers SC10 safety controller for small-to-medium robot cells

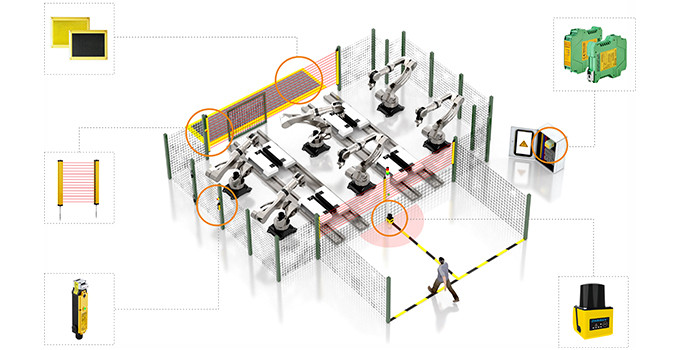

Typical Layout: Sensor Deployment in a Robot Palletizing Station

1. Safety laser scanners at front-left and rear-right corners to cover 270° zones

2. Light curtains across entrance gates and pallet exit conveyors

3. Interlock switches on all access doors to fencing

4. Safety relays in the control cabinet integrating all signals

5. E-stop buttons on each corner of the workstation

6. Safety mats at operator loading zones (optional, especially in collaborative robot setups)

Enhancing Safety Without Sacrificing Efficiency

Smart zoning, restart interlock, and dynamic muting strategies allow automated systems to maintain high throughput while staying compliant with ISO 10218-1 and ISO/TS 15066 standards. Modern systems also offer diagnostic and predictive maintenance features, reducing downtime.

Intelligent Solutions

DADISICK offers a competitive selection of industrial safety products:

● 2D Safety Laser Scanners for access protection and zone control

● Safety Light Curtains for finger, hand, and body protection

● Safety Interlock Switches for gate control

● Emergency Stop Devices and Safety Relays for logic integration

These products provide cost-effective alternatives to global brands with strong compatibility and flexible deployment. Contact us to learn more about how DADISICK can support your smart factory upgrades.

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety products are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.