Case Study of Safety Protection Upgrade in Automotive Production Lines, Cost Reduced by 30% with Alternative Solution

Safety Protection Upgrade in Automotive Production Lines, Cost Reduced by 30% with Alternative Solution

Customer Background

This case focuses on a Polish company specializing in the development and production of equipment related to automotive industrial production processes. In their daily operations, the company relied on Japanese brand light curtains integrated into their production equipment to ensure workplace safety. However, as their business expanded, they gradually encountered challenges such as delivery delays and high spare parts costs, which significantly impacted the company’s normal operations and cost control.

Challenges in Installing Safety Light Curtains

To address these issues and improve overall production efficiency, the company decided to upgrade its existing safety protection system. The main challenges faced during this upgrade included:

Time Constraints

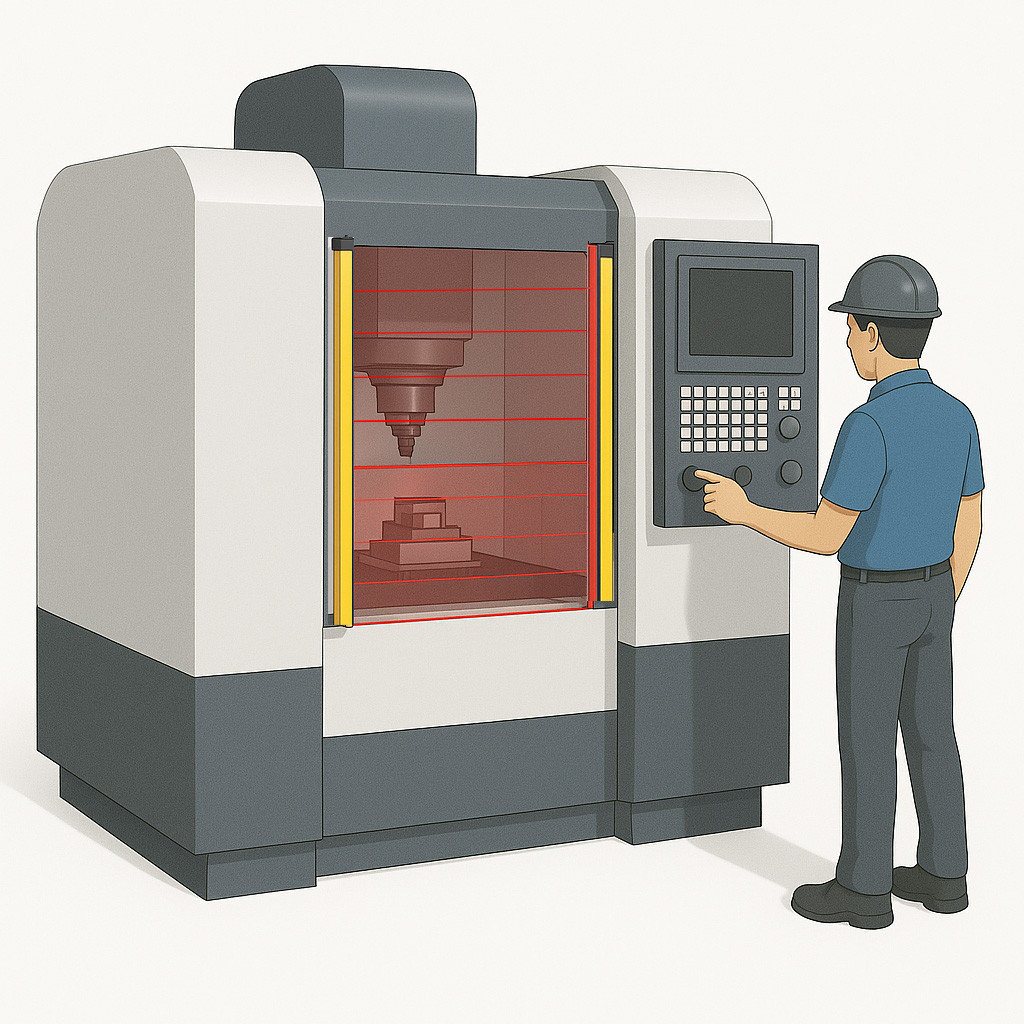

The new equipment had to be installed within a specified timeframe on the automotive production line, which operates year-round without interruption. Therefore, the replacement process had to be completed within 4 hours.Compatibility Requirements

The newly selected light curtain had to seamlessly integrate with the existing safety PLC (Programmable Logic Controller) to minimize additional adjustments and configuration work.Solution: Performance Comparison Between Keyence Safety Light Curtains and DADISICK

In response to these challenges, we proposed a comprehensive and efficient solution:

Early Evaluation Stage: Present a true and accurate comparison of performance between our safety light curtains and the original brand, helping customers make transparent and rational purchasing decisions.Offer flexible solutions for single-point replacement and system integration, avoiding bundled sales.

| Brand | Keyence safety light curtain | DADISICK safety light curtain | ||

| Model | GL-R95F | |||

| Beam spacing | 10 mm | 10 mm | ||

| Number of optical axes | 95 | 98 | ||

Protection height | 940 mm | 970 mm | ||

Detection distance | 0.2 to 10 m | 0.3 to 10 m | ||

Light source | Infrared LED (870 nm) | Infrared light (NlR),invisible, 850 nm | ||

Response time | 14.7 | ≤15 ms | ||

OSSD output | 2 transistor outputs. (PNP or NPN is determined by the cable type) | 2-circuit of output: NPN NC / PNP NC / NPN NO / PNP NO | ||

Connector | M12 | M16 | ||

Housing cross-section | 28 mm × 30 mm | 35 mm × 51 mm | ||

Synchronization between the transmitter and receiver | Optical synchronization or Wire synchronization (Determined by wiring) | Line synchronization | ||

Housing Material | — | Metal | ||

Metal Shell | Aluminum | Aluminum | ||

Lens Front Screen Material | Polycarbonate, SUS304 | Acrylic | ||

Upper and Lower Cover Materials | Nylon (GF 30%) | ABS Reinforced Nylon (PA66 + 30% GF) | ||

Protection circuit | Reverse current protection, short-circuit protection for each output, surge protection for each output | Short-circuit protection, Overvoltage protection | ||

Supply voltage | 24 VDC ±20%, ripple (P-P) 10% or less, Class 2 | 24 VDC, -20%...+20% | ||

Maximum current consumption | Transmitter: 71 mA; Receiver: 83 mA (At high temperatures (50–55°C), the load current must be limited to 350 mA) | 150 mA | ||

Fuse | — | 2 A, slow-blow fuse | ||

IP rating | IP65 / IP67 | IP65 | ||

Ambient Light Resistance | Incandescent lamp: 3,000 lux or less., Sunlight: 20,000 lux or less | Incandescent Light: 3000 lx (illuminance on the receiver surface) Sunlight: 10000 lx (illuminance on the receiver surface) | ||

Operating ambient temperature | -10 to +55 °C 14 to 131 °F (No freezing) | -10 to +40 °C (no freezing) | ||

Storage Temperature | -25 to +60 °C -13 to 140 °F (No freezing) | -25 to +55 °C | ||

Operating relative humidity | 15 to 85 % RH (No condensation) | 35~85% RH | ||

Storage relative humidity | 15 to 95 % RH | 35~95% RH | ||

Plug-and-Play Design: To simplify the installation process, we provided a specially designed “Pin-to-Pin Adapter Kit.” This adapter retained the original brand's interface definition, reducing the replacement time from several expected hours to just 2.5 hours. This greatly improved work efficiency while meeting the need for rapid switching.

Cost Comparison: By introducing our product, we not only resolved issues related to long delivery times and expensive spare parts but also reduced the Total Cost of Ownership (TCO) by approximately 30%. Below is a simplified cost comparison table:

| Cost Item | Original Solution (Japanese Brand) | New Solution (Our Product) |

| Initial Purchase Cost | $6500 | $4550 |

| Maintenance & Spare Parts Cost | High | Moderate |

Implementation Results: After project completion, the customer provided positive feedback: “We didn’t modify any PLC programs, but we gained better diagnostic functions.” This indicates that the new safety protection solution not only achieved seamless integration with the existing system but also brought additional functional improvements, enhancing the safety and reliability of the production line.

Recommended Safety Light Curtains

Key Features of the QMT Series Safety Light Curtains

1. Complies with CE safety category 4 standards, offering robust resistance against electromagnetic and optical interference.

2. Excellent vibration resistance, with superior waterproof and dustproof performance, ensuring stable operation even in demanding industrial settings.

3. Built-in diagnostic capabilities enhance system reliability and ensure real-time safety monitoring.

4. Supports ultra-long-distance beam alignment up to 45 meters, and protection heights up to 6 meters, making it ideal for large-area safety applications such as door protection and machine fencing.

Safety Light Curtain Replacement Solutions

View Catalog

Choosing Your Safety Solutions

You May Also Be Interested In

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety light curtains are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.