Safety Light Curtain Selection Guide – A Technical Decision Manual Based on IEC 61496 Standard

How to Choose the Appropriate Safety Level (Based on IEC 61496 Type Classification)

• Core Differences Between Type 2 and Type 4

| Parameter | TYPE2 (SIL1/PLc) | TYPE4 (SIL3/PLe) | ||

| Safety Level | SIL CL1 | SIL CL3 | ||

Fault Detection | Startup/Restart Check | Continuous Real-time Monitoring | ||

Redundancy Design | None | Yes (Dual Channel Redundancy) | ||

Effective Aperture Angle (EAA) | 5° | 2.5° | ||

Expansion Function | Basic Function (such as locking output) | Advanced Function (such as blanking, multi-communication, etc.) | ||

| Applicable Scenarios | Low-risk, General Industrial Equipment | High-risk, Complex Environment (such as stamping press) | ||

| Cost | Relatively Low | Relatively High | ||

• Selection Recommendations

Select TYPE2 When the equipment risk is relatively low, the budget is limited, and there is no need for complex expansion functions.

Select TYPE4 When the equipment involves high-risk operations (where the human body directly contacts hazardous areas) and requires high reliability or is used in complex environmental applications.

• Risk Assessment Tools

Apply dual verification using IEC 61496 Annex Risk Graphs and ISO 13855 safety distance requirements to ensure hazard identification matches safety levels.

Define the Protection Zone of Safety Light Curtain

1. Detection Range (Protection Zone)

• Horizontal Coverage: Select 3-45m beam distance based on equipment aperture

• Vertical Coverage: Beams must exceed mechanical movement trajectory by 20% safety margin (e.g., 1.2m coverage for 1m robotic arm stroke)

DADISICK Solutions: L/U-type mirror systems extend detection areas, tubular brackets adapt to compact spaces.

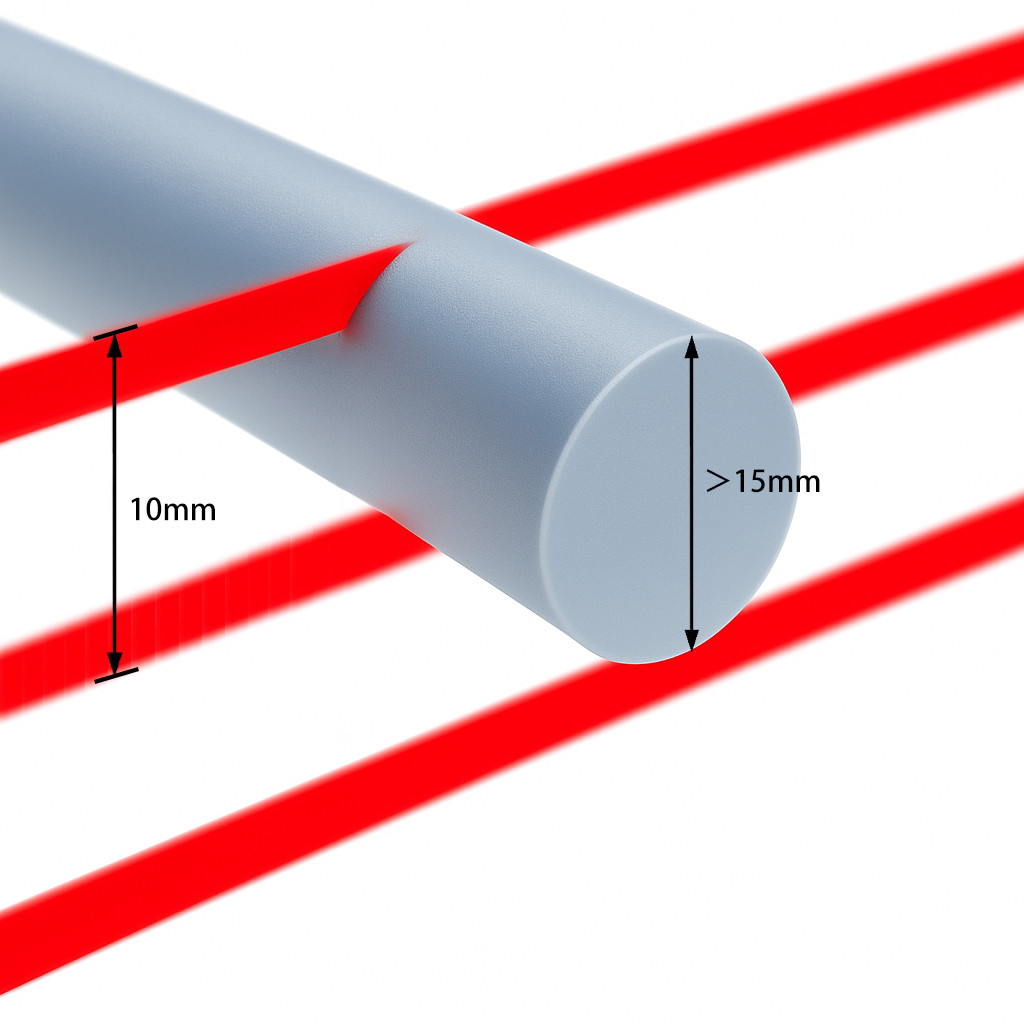

2. Resolution Selection Criteria

| Protection Object | Recommended Resolution | Application Scenario | |

| Finger | ≤14mm | Precision assembly areas | |

| Hands | ≤30mm | Material access ports | |

| Body | ≥40mm | Large equipment passages | |

• Key Formula: Detection accuracy ≥ 1.5×target object size (Example: ≤14mm resolution required for 10mm finger detection)

3. Calculate Safety Distance for Safety Light Curtain (ISO 13855)

Formula: S = 1.6 × T + √[(2h)/9.8]

S: Minimum safety distance (mm)

T: Total system response time (ms)

h: Hazard height from floor (mm)

Example: For T=120 ms, h=800 mm:

S=1.6×120+√[(2×800)/9.8]=319 mm

Evaluate Environmental and Technical Compatibility of Safety Light Curtain

1. Harsh Environment Resilience (Taking the QCE series general-purpose safety light curtain as an example.)

(1)Optical Interference Immunity

Compliant with IEC 61496-1 Annex E:

Incandescent light: Stable operation under ≤3,000 Lux

Fluorescent light: Zero false triggers at ≤3,000 Lux

Direct sunlight: Maintains detection under ≤10,000 Lux

(2) Certified per IEC 60068-2 series:

| Test Type | Parameters | Standard | |

| Vibration | 10-55Hz sweep/0.35±0.05mm amplitude, Three-axis, 20 cycles/axis | IEC 60068-2-6 | |

| Shock | 10g acceleration/16ms pulse duration, Three-axis, 1,000±10 impacts/axis | IEC 60068-2-27 | |

(3)Models with IP67/IP68/IP69K ratings suit environments such as food processing or chemical industries, offering excellent dust and water resistance. Featuring an all-metal casing design, our products operate reliably in temperatures from -10°C to +40°C and have passed vibration and shock tests according to IEC 60068.

2. Signal Output and System Integration

Our systems support both PNP and NPN dual-channel outputs as well as relay output, seamlessly integrating with mainstream PLCs (e.g., Siemens, Mitsubishi).

Hidden Cost Control in Installation and Maintenance

1. Optimized Installation Engineering Solutions

(1) Comparison of Synchronization Methods

| Parameter | Light Synchronization | Wire Synchronization | ||

| Wiring Complexity | No wiring required (wireless IR sync) | Requires sync cables (up to 30 meters) | ||

Anti-Interference | Susceptible to strong light interference | Electromagnetic shielding design, +30% stability | ||

Typical Applications | Mobile devices / Retrofit projects | Fixed heavy machinery | ||

Cost Difference | Lower initial cost, 15% higher maintenance cost | Higher wiring cost, lower lifecycle cost | ||

(2) Rules for Installation Positioning

L-type bracket application: Ideal for protecting corner areas of hazardous zones (e.g., the feed opening of a press machine).

Tubular bracket installation: Effectively minimizes the impact of vibrations during machine operation.

Brand and Supply Chain: A Practical Guide to Avoiding Pitfalls

Choose suppliers with independent R&D and in-house production capabilities. This ensures better quality control and long-term product support. Manufacturers like DADISICK offer both self-developed solutions and OEM partnerships, with full transparency on technical specifications and compliance.

Look for Certifications and Patents: Select suppliers with recognized credentials, such as “High-Tech Enterprise” status, “Specialized and Innovative Enterprise” certifications, and international approvals like CE and UL.

FAQ About Safety Light Curtain Selection

Q1: Can Type 4 curtains be used in Type 2 applications?

Yes, but conduct risk assessment to confirm cost-effectiveness.

Q2: How to verify curtain effectiveness post-installation?

Use DADISICK laser distance measurement for beam alignment and response verification.

Q3: Does multi-mirror reflection compromise safety?

Maintains Type 4 performance with ≤2 reflections when using certified retroreflectors.

Safety Light Curtain Replacement Solutions

View Catalog

Choosing Your Safety Solutions

You May Also Be Interested In

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety light curtains are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.